A small motor was used to rotated the upper glass slide at a constant rate of 0.5

revolutions per hour, which produced a relatively smooth, non-coaxial

circular (Figure 5).

Couette flow in the paraffin in the annular shear zone. Flow lines are circular

but parallel to the frosted grips and the flow pattern therefore bears a resemblance

to that of simple shear: no stretching occurs parallel to the grips. A circle parallel

to grips is defined as flow circle, similar to the flow plane of simple shear

Couette flow in the paraffin in the annular shear zone. Flow lines are circular

but parallel to the frosted grips and the flow pattern therefore bears a resemblance

to that of simple shear: no stretching occurs parallel to the grips. A circle parallel

to grips is defined as flow circle, similar to the flow plane of simple shear

(Ten Brink & Passchier 1995). The experiment was conducted at a homologuous temperature

(T/Tmelting) of 0.88. The circular shape of the specimen chamber induces a gradient

of increasing flow stress and strain rate over the sample. A gradient in shear strain

rate

(Ten Brink & Passchier 1995). The experiment was conducted at a homologuous temperature

(T/Tmelting) of 0.88. The circular shape of the specimen chamber induces a gradient

of increasing flow stress and strain rate over the sample. A gradient in shear strain

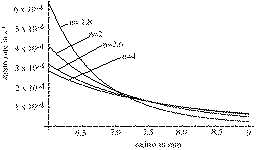

rate ![]() exists, decreasing in paraffin from

inner shear zone boundary to the outer in relation to

exists, decreasing in paraffin from

inner shear zone boundary to the outer in relation to ![]() ,

where r is the distance from a position in the annular shear zone the rotation

axis (Figure 6) (Masuda 1994). The imposed annular shear strain (

,

where r is the distance from a position in the annular shear zone the rotation

axis (Figure 6) (Masuda 1994). The imposed annular shear strain (