To further investigate the model of Urai et al. (1991), a computer program was written to simulate the crack-seal process. The model is only briefly described here, and the reader is referred to the full description of the model and a first systematic investigation with the model that are given by Bons (in press a) and Hilgers et al. (in press). In the 2-dimensional model, grains are defined by nodes that are linked by straight boundary segments. An initial horizontal surface fracture is created with a user-defined roughness. Every N time steps, the lower fracture surface is moved a user-defined distance and direction to simulate a crack-opening event. All grain surfaces that are then exposed to the open fracture grow outward by repeatedly moving the boundary segments over small distances one at a time. The segments are moved until they reach the other side of the fracture space (Fig. B2). The rate of growth is a function of the angle (a) between the boundary segment and the c-axis of a grain, which defines the lattice orientation. The type of function defines the growth habit of the crystal and therefore different "minerals" can be defined. In the examples below, two "minerals" were used:

- "Square mineral". The growth rate is fastest in the directions parallel and perpendicular to the c-axis. The habit of this mineral is that of a square.

- "Prismatic mineral". Growth is fastest parallel to the c-axis and slowest normal to it. A secondary growth rate minimum occurs at 30° to the c-axis, which gives the mineral a quartz-like prismatic habit.

Growth in an open cavity

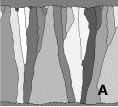

Growth in an open cavity best illustrates the effect of different mineral

types on the morphology of the vein fill. Figure B3.a shows the result

of 800 growth steps of the prismatic mineral into a wide open fracture

with a rough surface. The shading of the grains is a function of the c-axis

orientation. One can see that the grains with a vertical c-axis (light)

quickly outgrow differently oriented grains. Figure B3.b shows the same

for 640 growth steps for the square mineral. Both grains with vertical

(light) as well as with horizontal (dark) c-axes are now the "winner" grains.

Crack-sealing with a vertical opening trajectory - effect of crack-width

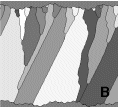

Three movies (Fig. B4) show the effect of the crack width. Figure B4.a

shows growth in many (154), but small (2 pixels) vertical fracture opening

events. Grain boundaries quickly get locked on ridges, resulting in little

reduction in average grain width as growth progresses. The spacing of the

ridges determines the width of grains. If, keeping all other parameters

the same, the fracture opening is doubled to four pixels per event (Fig.

B4.b), we see a decrease in locking capability of the ridges and a slightly

larger average grain width developing. Increasing the fracture width to

16 pixels (Fig. B4.c) results in almost complete loss of locking capability

of ridges. These simulations confirm the model of Urai et al. (1991),

that the locking capability of ridges is a function of the width of the

fracture relative to the roughness of the fracture. The rougher a fracture

and/or the thinner the fracture, the better is the locking capability and

hence the tracking capability of the vein crystals. The spacing between

ridges determines the average crystal width when locking is strong.

Crack-sealing with an oblique opening trajectory - effect of crack roughness

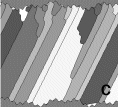

Figure B5 shows three movies of growth with an oblique (Dx=-2

& Dy=4) opening direction, while all other

parameters are kept the same except the roughness amplitude. The fracture

surface is too smooth in Fig. B5.a for any ridges to lock grain boundaries.

The average grain width increases in the growth direction and there is

no tracking whatsoever of the oblique opening direction. Doubling the amplitude

of the roughness (Fig. B5.b) leads to locking of some boundaries, but not

all. Therefore, some boundaries follow the oblique opening trajectory,

while others grow vertically. The result is a specific microstructure with

some strongly elongate grains, some large blade like crystals and many

"looser" grains (see Fig. 1.c in Bons & Jessell 1997). A further increase

in surface roughness (Fig. B5.c) produces a better locking capability of

the ridges and hence better tracking of the opening trajectory.

Crack-sealing - change of opening direction

Finally, a case of growth with an abrupt change of opening direction

is shown in Fig. B6. The case shown is for isotropic growth with a rough

fracture surface, resulting in perfect tracking of the opening trajectory

in the first growth period. After an abrupt change in opening direction,

perfect tracking is maintained, but several fibres get truncated soon after

the change in direction. Such a sudden increase in average fibre width

is often seen associated with a change in opening direction (Fig. 14.b).

The change in opening direction causes a change in the points where grain

boundaries are locked. Temporary unlocking during the transition period

frees the grain boundary for lateral movement and possibly the truncation

of the grain.