4. Experimental Examples

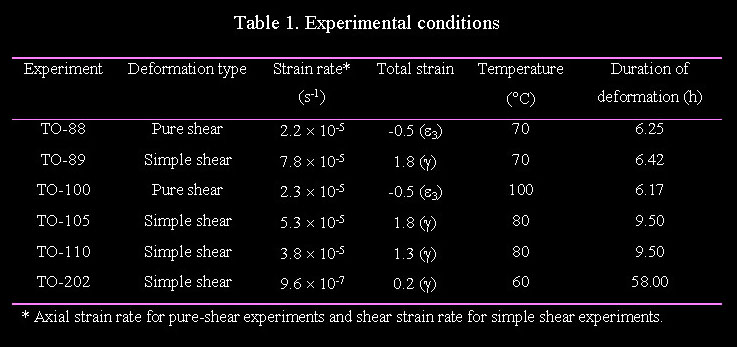

We deformed thin sheets of octachloropropane (C3Cl8, hereafter called OCP) mixed with marker particles (1000-grit silicon carbide) in a ‘Urai press’ mounted on the stage of an optical microscope for in situ observation and recording of deformation processes. This technique of ‘synkinematic microscopy’ is explained by Means (1989). Table 1 below shows the experimental conditions. Deformation temperature and strain rate are 60-100° C (75-85% of absolute melting temperature of OCP) and 10-5-10-6/sec, respectively. OCP under these conditions show mostly crystal-plastic behavior. Other details of sample preparation, experimental conditions, analytical methods and general deformation pictures are given by Ree (1991, 1994).

4.2. Grain Boundary Sliding by Translation Jump and Accommodation by Diffusion (TO-110)

Figure 3 and its associated movie show grain boundary sliding induced by a translation jump in sample TO-110. In Fig. 3a (bulk shear strain = 0.1), eight material lines were drawn approximately perpendicular to the shear direction with the help of marker particles. After an additional local bulk shear strain of 1.2, all material lines are stretched and rotated (Fig. 3b). All material lines, except two lines passing through grains 95 and 96, remain more or less parallel to each other without any offset. These two lines show offset of about 75 micrometer across the boundary between grains 95 and 96. Grain 95 is not strained much with its basal slip plane is almost perpendicular to the shortening direction. Grain 95 thus is a 'hard' grain with the basal plane unfavorably oriented for slip (Ree 1990). Grain 96 on the other hand is strained almost the same as the bulk strain ellipse for the whole group of grains. Without grain boundary sliding this strain difference should have been represented by a kink-like feature of the material lines without any offset. The offset of the lines running through the two grains implies grain boundary sliding in which grain 95 is translated more or less rigidly over grain 96. All these features can be clearly seen in the movie of Fig. 3.

At the extensional site associated with the rigid translation of grain 95, the grain boundary sliding is accommodated by diffusional flow. The area occupied by four marker particles across the grain boundary at extensional site increases continuously with the deformation (Fig. 4). The total increase in area is about 50% at the end of the deformation. Diffusional influx of material should accounts for this area increase. At the compressional site (boundary between grains 95 and 100, Fig. 3a), the exact accommodation mechanism is unclear due to lack of marker particles there.

Grain sliding along the boundary approximately parallel to the bulk shear direction as described above was found at 8 sites in this sample, mainly around hard grains. The amount of offset is usually 70 - 80 micrometer, or 0.6 - 0.7 the average grain diameter. In this sample, however, the contribution of grain boundary sliding to the total strain is minor, accounting for only about 3% (Ree, 1994). Ree (1991, 1994) described the microstructural evolution of this sample in detail.

4.3. Grain Boundary Sliding by Strain and Rotation Jumps (TO-110)

In this example, grain boundary sliding induced by strain and rotation jumps is shown. The strain and rotation jumps result from the difference in initial orientation of the basal slip plane between two grains. It was not possible to identify the accommodation mechanism due to a lack of marker particles.

Figure 5 shows the c-axis orientations and marker particle trajectories of grains 76 and 78 for a period of deformation during which a bulk shear strain of about 0.7 has accumulated from the stage in Fig. 3(a). The trend of the basal slip plane in grain 76 inclined toward the shear direction at the beginning of the deformation, and its c-axis rotated clockwise by about 25o after an interval of deformation in Fig. 5. On the other hand, the trend of the basal slip plane in grain 78 inclined against the shear direction at the beginning of the deformation and its c-axis stayed in almost the same position (Fig. 5a). The trajectories of marker particles in grain 78 relative to a fixed point within this grain show displacements approximately parallel to the trend of its basal slip plane, suggesting basal slip is the primary deformation mechanism in grain 78 (Fig. 5b). The trajectories of marker particles in grain 76 relative to a fixed point within this grain also tend to show displacements parallel to the trend of its basal plane (Fig. 5c), but whether basal slip predominates or not is unclear because of the rotation of its c-axis. The deformation of these two grains with different displacement fields results in different maximum stretch (S1) directions (44o vs. 25o CCW from the shear direction) and in different rotations of S1 (25o vs. 18o CW), even though the stretch ratios in the two grains (1.9 vs. 2.1) do not differ greatly (Fig. 5b).

In Fig. 6(a) a material line was drawn almost perpendicular to the boundary between the two grains using marker particles within the grains. This material line is approximately parallel to the trend of the basal slip plane in grain 78 and at a high angle to that of the basal slip plane in grain 76. As expected with basal slip, the segment of the material line in grain 78 does not change its length and orientation with increasing deformation. If other slip systems had been associated with basal slip, the material line initially parallel to the basal plane should have changed at least its length. On the other hand, the segment of the material line in grain 76 becomes shortened and rotated, producing an offset of the line of about 80 micrometer at the end of the deformation (Fig. 6d). Therefore it is believed that this offset represents grain boundary sliding induced by a strain jump or difference in the maximum stretch direction and a rotation jump between grains 76 and 78.

4.4. Grain Boundary Sliding by Translation Jump and Accommodation by Grain Boundary Opening and Intracrystalline Plasticity (TO-105)

Although experimental conditions of TO-105 were almost the same as TO-110 except for the initial c-axis orientation (see below), its deformation behavior was strikingly different from TO-110, with an extensive development of grain boundary openings (Fig. 7) and a greater component of grain boundary sliding in its total deformation. In preparation of an OCP sample before deformation, some preferred orientation of c-axes is always introduced due to the pressing of the sample between two glass slides perpendicular to the plane of observation to obtain a desired sample thickness (30 - 40 micrometer) and some preferred extrusion along the deformation window during sample pressing. The usual shape of c-axis preferred orientation before deformation is a broad, single girdle normal to the direction of shear in simple shearing experiments as in TO-110 and TO-202 (see Fig. 11f). But in sample TO-105 the initial c-axis orientation forms a girdle at a low angle to the shear direction for some unknown reason (Fig. 8a).

Figure 8 shows c-axis fabric diagram before and after deformation, and c-axis reorientation trajectories of some grains in the central area of the sample. During dextral simple shear, the intragranular plastic deformation of grains is accompanied by clockwise rotation of c-axes (Fig. 8c). When the c-axes of most grains are in positions unfavorable for basal slip, grain boundary openings begin to occur in association with relatively rigid translation and rotation of most grains in the sample (Figs. 7 and 8c). Grain boundary openings develop preferentially along boundaries at a low angle to the shortening direction, inclining against the bulk shear direction or the direction of relative displacement of the upper part of the shearing sample. Their widths range from about 2 micrometer up to 40 micrometer with a typical width of about 5 micrometer or about 0.04 the average grain diameter. Their lengths, ranging from about 15 micrometer to 200 micrometer, are mostly 50 micrometer or about 0.4 the average grain diameter. Grain boundary openings grow rapidly during initial stages of deformation to occupy 1 - 2% of the sample area, and remain constant at that value until the deformation stops. Further details of the evolution of these grain boundary openings will be explained later. In this sample, the contribution of grain boundary sliding to the total strain is about 25% (Ree, 1994).

An example of grain boundary sliding resulting from translation jump is illustrated in Fig. 9 which shows grain boundary maps, marker particle trajectories and c-axis trajectories for three grains in the sample during an interval of the deformation. The three grains are deformed mainly by intragranular plastic deformation and their c-axes rotate clockwise by 10 - 30o during bulk shear strain of about 0.9 (Figs. 9a and b). As the basal planes of the grains approach an orientation unfavorable for slip, the deformation becomes dominated by grain boundary sliding, and openings begin to develop preferentially along boundaries at a low angle to the shortening direction (Figs. 9c, d, e and f). With an additional shear strain of about 0.4 from the stage of Fig. 9(a), a material line defined by marker particles across the grains 22 and 11 shows an offset of about 100 micrometer or about 60% of the average grain diameter of the sample (Fig. 9e). The maps of marker particle trajectories in Figs. 9(d) and 9(f) indicate that this grain boundary sliding results mainly from a translation jump between grains 11 and 22.

Across the grain boundaries under possible compression due to the grain boundary sliding, such as the boundary between grains 11 and 3a, and the boundary adjacent to the junction of grains 3a, 3b and 22 (Fig. 9e), the areas occupied by each four marker particles show only a few percent decrease from the stage of Fig. 9(c) to Fig. 9(e). This implies that diffusional accommodation is not significant at these sites. Note also that the grains are not perfectly rigid but are internally strained during grain boundary sliding. Grain 3 is more strongly strained than the other grains and shows rotational recrystallization resulting in grain-size reduction. This suggests that grain boundary sliding is accommodated mainly by intragranular plastic deformation at these compressional areas. At boundaries possibly under extension, grain boundary sliding causes openings to occur that could serve as sink sites of diffusion. Indeed, some grains show overgrowths into the grain boundary openings, suggesting diffusional influx into these sites (Fig. 7 and also see figs. 7e and f of Ree, 1994). The source sites of diffusion are not clear given the marker particle population and scale.

4.5. Grain Boundary Sliding by Rotation Jump and Accommodation by Grain Boundary Opening (TO-105)

Figure 10 shows grain boundary sliding due to a rotation jump between grains 25a and 26 in sample TO-105. As the sample is deformed , intragranular plastic deformation and clockwise c-axis rotation are followed by the formation of grain boundary openings, as in the previous example. After a bulk shear strain of about 1.2 (Fig. 10a), the two grains deform in significantly different manners. The trajectories of marker particles within grain 25a (Figs. 10d and f) and very weak intragranular deformation implied by the incremental, intragranular strain ellipses (Figs. 10c and e) indicate that grain 25a is deformed mainly by clockwise rigid-body rotation. The c-axis of grain 25a also rotates clockwise by about 20o (Fig. 10b), and its grain-size increases with the consumption of adjacent grains during this deformation interval. In contrast, the intragranular strain of grain 26 is stronger even than the bulk strain of the local area comprising these two grains. Grain 26 also shows grain-size reduction by rotational recrystallization and grain boundary migration (Figs. 10a, b, and c), and only a small rotation of its c-axis (Fig. 10b). Grain boundary sliding associated with the more or less rigid-body rotation of grain 25a is evidenced by the offset of a marker line drawn almost perpendicular to the boundary between the two grains. The healing and shape change of openings at the NE and SW boundaries of grain 25a, and the creation of openings at the boundary between grains 25a and 26, are associated with this grain boundary sliding (Fig. 10e). The reason why the two grains behave differently, even though the orientations of their c-axes relative to the shear direction are similar at the beginning of the deformation interval described above, is unclear. Perhaps the stress field is highly heterogeneous in that area.

4.6. Grain Boundary Sliding by Translation Jump and Accommodation by Diffusion and Grain Boundary Opening (TO-202)

Experiment TO-202 is the slowest simple shearing experiment described here (Table 1). The c-axis fabric diagram before deformation shows a broad girdle normal to the direction of shear as usually observed in other simple shearing experiments (Fig. 11f).

As in experiment TO-105, extensive grain boundary openings associated with grain boundary sliding develop. They develop, however, at a lower shear strain than in TO-105 (less than 0.1). Their ratio is about 1 % of the sample area at shear strain of 0.1. Offset of a marker particle line and marker particle trajectories in Fig. 11 indicate that a translation jump is mainly responsible for the grain boundary sliding between grains 4 and 6 (Figs. 11a, b and c). Across a boundary which is possibly under compression due to the grain boundary sliding, the area occupied by four marker particles decreases by about 15% during an increment of bulk shear strain less than 0.1 (Figs. 11d and e), suggesting the removal of material by diffusion. The upper segment of the boundary between grains 4 and 7 (41 in the earlier stage) moves toward the marker particles in grain 4 as well as toward those in grain 7 (41 in the earlier stage, Figs. 12a and b). This suggests material flux from both grains along the boundary. The lower segment of the boundary moves toward the marker particles in grain 4 and away from those in grain 7. The distance of the boundary movement toward the marker particles in grain 4 is larger than that of the boundary movement away from the marker particles in grain 7 (Figs. 11a and b). This may indicate that material flux from grain 4 occurs together with the conventional volume-conserving grain boundary migration for the lower segment of the boundary. At an extensional site (the left boundary of grain 4), a grain boundary opening develops by grain boundary sliding. Preservation of contact between grain 4 and the grain to its left (not shown) along the lower part of the boundary, however, implies that a translation of the grain on the left or diffusional influx may also be involved at this site.