5. Evolution and Implications of Grain Boundary Sliding

The experimental examples show that openings grow preferentially along grain boundaries at low angles to the shortening direction with grain boundary sliding. Growth of openings usually involves four grains (Figs. 12a and c). Once openings grow, they are shortened parallel to the shortening direction by thrusting of sliding grains and grain overgrowth into the openings. With further deformation they are eventually closed leading to a neighbor switching of four grains (Figs. 12a and c). The magnitude of the minimum principal stretch associated with this neighbor switching is about 0.7. This value is somewhat larger than that (0.58) of Ashby and Verrall's (1973) neighbor switching model where coherency at the boundary is maintained by diffusion without opening. In some cases only two or three grains are involved in the opening and closing of a grain boundary without any neighbor switching (Fig. 12b). Here grain boundary openings are closed as one grain rigidly rotates and the grain boundary with openings becomes perpendicular to the shortening direction.

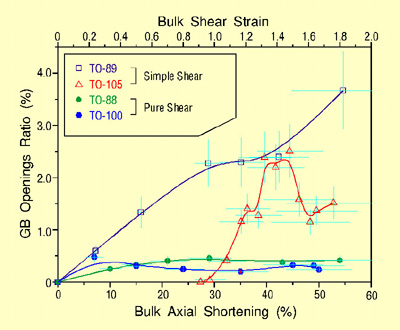

While grain boundary openings are being closed in some places, approximately the same area of grain boundary openings appear in other places, maintaining an approximately steady openings ratio of about 1 - 3% of the sample volume in these simple shearing experiments and of about 0.5% in pure shearing experiments without development of any large scale fracture (Figs. 7, 13 and 14). In one simple shearing experiment (TO-89), however, the ratio increases by a further 1% toward the end of the deformation. The mean residence time of individual openings corresponds to a shear strain increment of about 0.2 in experiment TO-105 (Ree, 1988). Almost all grain boundary openings disappear within 15-20 hours if the deformation is stopped but the temperature is maintained (Fig. 14).

In Fig. 15, the orientations of grain boundary openings at the end of the deformation are shown as rose diagrams with the foliation orientation as a reference horizontal axis. The foliation orientation is defined statistically by the preferred orientation of long axes of grains in this paper. In experiments TO-89 (simple shearing experiment) and TO-88 (pure shearing experiment) the openings are preferentially oriented at a high angle to the foliation orientation. Their orientation is also symmetric with respect to the foliation orientation (Figs. 15a and c). In experiment TO-105, however, the preferred orientation of the grain boundary openings is at a low angle to the foliation orientation (Fig. 15b). However in this experiment, the average ratio of long axes to short axes of grains is very low (about 1.05). With this low value of average grain axial ratio, the definition of foliation orientation is of uncertain significance. In all experiments, the preferred orientation of grain boundary openings is at a high angle to the direction of the maximum finite stretch, and at a low angle to the shortening direction (Fig. 15). The orientations of grain boundary openings were also measured at several stages during deformation. They all show more or less constant distribution with respect to the shortening direction as in Fig. 15.

These grain boundary openings are strongly coupled with grain boundary sliding as explained earlier, and they can also significantly enhance diffusion by providing paths for rapid transport of matter through fluids filling the openings (White and White, 1981; Raj, 1982). In natural conditions, fluid will probably circulate preferentially toward growing grain boundary openings and away from closing grain boundary openings. This circulating fluid will shift the sites at which reaction and alteration are concentrated, and will redistribute chemical components (Cox and Etheridge, 1989; McCaig and Knipe, 1990). More importantly, the creation of grain boundary openings dramatically increases the area through which diffusion can take place, thus enhancing the rate of diffusional transport.

The preferred alignment of grain boundary openings at low angles to the main shortening direction both in pure and simple shearing deformation (Fig. 15) suggests that it may be used as an indicator of the instantaneous stretching or flow stress orientation in situations where older, rotated openings are continuously removed.

The ratio of grain boundary openings is lower in pure shearing deformation than in simple shearing deformation (Fig. 13). This difference may result from the deformation configuration of the present apparatus where a thin sheet of OCP is deformed between two glass slides (see Means, 1989, fig. 1c and d). In simple shearing configuration there exists a tension along the stretching direction whereas there is no tension, only a weaker compression, along the stretching direction in pure shearing deformation. The presence of tension in the simple shearing experiments probably facilitates the development of grain boundary openings.