Lab 2b- Recrystallisation in analogue materials.

CET/UWA Microstructure Course

CET/UWA Microstructure Course

| TOC

| Lecture 1

2

3

4 a

b

5 a

b

| Lab 1 a

b

c

2 a

b

c

3 a

b

4 a

b

5 a

b

| Glossary Table

1

2

3

4

5

Index

| GEOS5505 Lab 1

|

We have four movies of static, dynamic, and metadynamic recrystallisation

in octachloropropane.

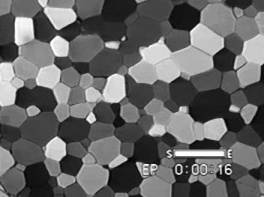

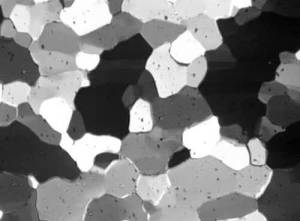

A) Grain Growth.

In this experiment, we start out with a nice foam texture, and end up

with a nice foam texture, and in between we have a nice foam texture. This

is characteristic of static grain growth.

-

What are the characteristics of the grain boundary

geometries seen in this experiment?

-

Is there a relationship between the number of sides

a grain has and the curvature of its boundaries?

-

What is the driving force for grain boundary migration

in this experiment?

-

What is the relationship between grain size and whether

a grain shrinks or grows?

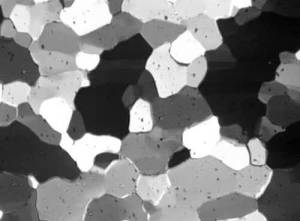

B) Dynamic recrystallisation. This movie is an extended version

of one of the movies in the first lab. Now we can find out if your predictions

for further microstructural development are true. The white areas that

develop around grains show areas where the grain boundary is no longer

perpendicular to the surface of the glass, so that you are looking through

two grains separated by a grain boundary.

-

Sketch the grains A & B at 4 stages of this experiment,

and label the deformation processes involved in the evolution of grains

A & B.

-

Look at Grain C and its neighbours below it, how

does the grain boundary change through the experiment, and why might this

change occur?

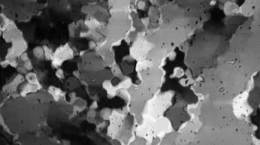

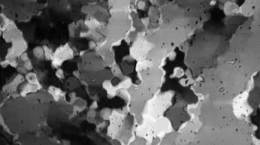

C) Dynamic and meta-dynamic recrystallisation. In this pair of movies

we start off with a foam texture, deform it in pure shear, stop the deformation,

and watch it return to a foam texture. At the end of this first movie the

motor was stopped and the further evolution of the microstructure is controlled

by its internal state at that time.

-

Using the dust particles as markers of material points,

how much shortening has the sample undergone by the end of the first movie?

-

What is the direction of maximum flattening, and

is this parallel to the grain shape foliation orientation?

Pure shear deformation of OCP

-

In the second movie (below) the behaviour of the

aggregate is very different in the first half of the movie than in the

second half, how and why does the behaviour change (eg why might the driving

forces evolve even though the motor has been turned off) ?

Post deformation behaviour of OCP following pure shear as seen above

CET/UWA Microstructure Course

CET/UWA Microstructure Course CET/UWA Microstructure Course

CET/UWA Microstructure Course