CET/UWA Microstructure Course

CET/UWA Microstructure Course CET/UWA Microstructure Course

CET/UWA Microstructure CourseGEOS 5505 Microstructure Prac Day 2

1) Polyphase Deformation

Question 41:Look at the examples of two-phase flow (microstructures and strain grids) then at the Two Phase Deformation Template before estimating the strain and rheological contrast betwen the different phases in the three natural examples

Two Phase Deformation Simulations File Name Key: Viscocity Ratio_% hard phase_stress exponent e.g. all_blobs.5_30_1.2.gif is an experiment with a viscocity ratio of 5; 30% hard blobs and a stress exponent of 1 (last number does not matter)

Two Phase Deformation Simulations with strain markers

Question 41b: How does the deformation change as you increase the viscocity ratio, as you increase the % hard phase and as you increase the stress exponent?

3D Polyphase deformation sample

natural examples 1 (top picture)

Question 42:These three natural examples show similar mechanical behaviour at two different scales. In spite of the apparently similar behaviour What DIFFERENCES are there between the small and large scale deformation?

Three Phase Deformation

Question 43:What are the relative mechanical strengths of the three minerals in the movies below? Describe the evolution of localisation behaviour by comparing the microstructure and deformed grid animation

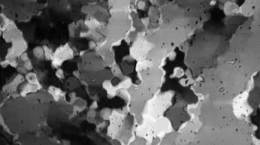

Three Phase Deformation Microstructure Assume grey is mica, pink is feldspar and white is quartz

2)Computer simulations of deformation processes.

The first part of the lab consists of a series of computer simulations of various grain scale deformation mechanisms & processes.

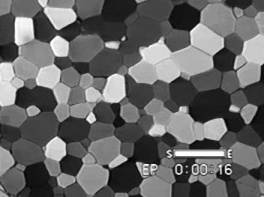

1) Static Grain Growth ![]() Simulation. This is a computer simulation of

grain growth in a single phase rock, such as a quartzite or a marble, and

was developed by Paul Bons. First of all go and have a look at the movie

of grain growth, and then answer the question below. In this simulation

the only driving force for grain boundary migration is the minimisation

of surface energy via the minimisation of grain boundary curvature. The

boundaries all migrate towards their centre of curvature. Static Grain

Growth Movies: There are 2 movies called NORMAL GROWTH and PINNED GROWTH,

and to run them double click on the icon and play with the slider control

at the bottom of the window.

Simulation. This is a computer simulation of

grain growth in a single phase rock, such as a quartzite or a marble, and

was developed by Paul Bons. First of all go and have a look at the movie

of grain growth, and then answer the question below. In this simulation

the only driving force for grain boundary migration is the minimisation

of surface energy via the minimisation of grain boundary curvature. The

boundaries all migrate towards their centre of curvature. Static Grain

Growth Movies: There are 2 movies called NORMAL GROWTH and PINNED GROWTH,

and to run them double click on the icon and play with the slider control

at the bottom of the window.

i) The NORMAL GROWTH movie shows the behaviour of a polycrystalline aggregate when left to its own devices, without deformation, at a high enough temperature that grain boundaries are mobile. As you can see the number of grains decreases, and hence the grain size goes up. Four grains have been coloured in so that you can follow them.

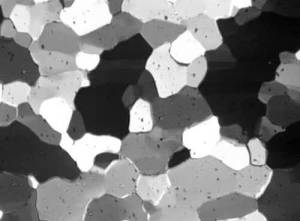

ii) The PINNED GROWTH takes over (at time =2000) from where the previous movie left off, except that a number of second phase particles have been added, and the grain boundaries find it hard to migrate through these particles. (These particles are green circles if they are found inside a grain, or red circles if they happen to be on a grain boundary). This is known as pinning and is very commonly observed in quartz-mica rocks, where the micas pin the grain boundaries. Notice how the grain growth virtually stops after a while. In this movie the colours of grain refer to the number of sides each grain posses (ie how many neighbours it has).

iii)

Start of simulation without pinning

End of simulation without pinning

End of simulation with pinning

3) We have four movies of static, dynamic, and metadynamic recrystallisation in octachloropropane.

A) Grain Growth.

In this experiment, we start out with a nice foam texture, and end up with a nice foam texture, and in between we have a nice foam texture. This is characteristic of static grain growth.

B) Dynamic recrystallisation. This movie is an extended version of one of the movies in the first lab. Now we can find out if your predictions for further microstructural development are true. The white areas that develop around grains show areas where the grain boundary is no longer perpendicular to the surface of the glass, so that you are looking through two grains separated by a grain boundary.

C) Dynamic and meta-dynamic recrystallisation. In this pair of movies we start off with a foam texture, deform it in pure shear, stop the deformation, and watch it return to a foam texture. At the end of this first movie the motor was stopped and the further evolution of the microstructure is controlled by its internal state at that time.

Pure shear deformation of OCP

Post deformation behaviour of OCP following pure shear as seen above

Copyright Mark Jessell & Paul Bons 2019